Technical Explainer: Clean and Improved Cookstove Carbon Credits

RMI experts analyze market trends, quality criteria, and risk implications for improved cookstoves carbon credits.

The Carbon Markets Initiative (CMI) developed these technical explainers to give buyers, developers, researchers, and other voluntary carbon market (VCM) stakeholders a head start in understanding individual carbon credit types. These explainers synthesize insights from publicly available methodologies, market analyses, registry data, project design documents, peer-reviewed literature, industry reports, regulations, best practice guidance, and commentary from both VCM and sector-specific sources. We complemented this research with expert interviews and a peer-review process. In each explainer, you’ll find a clear and neutral overview of:

- How developers generate carbon credits

- History and trends in the market

- Key quality risks and how projects address them

- Prospects and where the market might go next

Our goal is to complement — not replace — project-level due diligence. These explainers help stakeholders identify where to look more closely at project design to spot potential risks or safeguards.

What Does Our Risk Evaluation Entail?

In these explainers, we assess the magnitude (“severity”) and commonality (“prevalence”) of risks to seven quality criteria: additionality/baselines, leakage, permanence/durability, greenhouse gas accounting, MRV (monitoring, reporting, and verification), and socio-environmental impacts. CMI recognizes that quality is determined at the project level, not the credit type level. Thus, high or severe risks in a particular quality criterion do not mean that the entire credit type is of poor quality. For more information on how we assess risk, see the Appendix.

Executive Summary

Clean and improved cookstove carbon credits target emissions from traditional, fuel-based stoves in low- and middle-income countries (LMICs), where 2.3 bilion people rely on wood, charcoal, coal, or kerosene for cooking. These stoves pose compound threats — endangering millions of lives annually from indoor air pollution while accounting for at least 2% of global greenhouse gas emissions and threatening global forests. These are among the oldest credit types on the VCM: more than 181 million credits have been issued since 2004 from projects that help households transition to cleaner fuels and/or more efficient stoves.

However, these projects are complex and highly context dependent. Local fuel availability, infrastructure, cultural practices, individual preferences, and even seasonality can impact cooking behaviors, making proper design and monitoring critical to project success. Unfortunately, some of the foundational methodologies imperfectly captured this complexity, leading to increased scrutiny and allegations of over crediting. However, as the scientific understanding of how to account for emissions from cooking and human behavior change have evolved, so have the VCM standards.

Recent years have seen major methodological advancements. Three active protocols – Verra’s “Energy Efficiency and Fuel-Switch Measures in Cookstoves” (VM0050) and Gold Standard’s “Technologies and Practices to Displace Decentralized Thermal Energy Consumption (TPDDTEC)” methodology and “Methodology for Metered and Measured Energy Cooking Devises” (i.e. ‘Metered and Measured’) – have recently earned the Core Carbon Principles (CCP) label, indicating they apply robust accounting practices. In addition, the Clean Cooking and Climate Consortium (4C), led by the Clean Cooking Alliance (CCA), is finalizing the CLEAR methodology, which will establish a new, high-caliber bar for cookstoves projects in the voluntary and compliance markets.

Despite this progress, key risks to quality remain for buyers, including:

- Inflated fraction of non-renewable biomass (fNRB) values for projects not aligned with CCP requirements,

- “Rebound” effects, where in some cases, fuel use increases after stove adoption,

- Social desirability bias, which may make it difficult to detect stove stacking (using both project and conventional stoves) through kitchen performance tests (KPT) alone, and

- Sampling and implementation bias, which can increase the uncertainty of project monitoring.

Savvy buyers can mitigate these risks through due diligence measures such as:

- Using the peer-reviewed MoFuSS tool either to calculate the fNRB value or to select a default fNRB value,

- Measuring total household fuel consumption before and during project activities using KPTs,

- Employing direct monitoring technologies (e.g., meters/data loggers or fuel purchase records) to mitigate stove stacking, and

- Implementing rigorous sampling practices that are appropriate to the project context, like including larger sample sizes and/or using stratified random sampling.

Cookstove credits are entering an accelerated phase of reform. Projects are beginning to issue credits with the updated methodologies, and the CCP approvals are a promising sign that cookstove projects will become reliable sources of high-quality credits. With robust monitoring, design, and accounting principles that are aligned with industry best practices, these credits can catalyze vital financing towards one of the most critical and widespread climate and development challenges.

Credit Type Overview

This projects target traditional cookstoves: a pervasive threat for local ecosystems and just over a quarter of the world’s population. Roughly 2.3 billion people rely on basic, inefficient stoves that burn wood, coal, charcoal, or kerosene for their daily cooking needs. These traditional stoves produce roughly 2.3% of global greenhouse gas emissions (GHGs) and expose the users (disproportionately women and children) to daily doses of black carbon, carbon monoxide, and particulate matter 2.5 (PM2.5). Every year, between 3.2 million and 3.7 million people worldwide die early due to smoke inhalation and indoor air pollution from traditional stoves. Women and children can spend up to 5 hours per day gathering fuel — often by chopping down increasingly thinning forests — time that could be spent on education or other income-generating activities.

Clean and improved cookstove projects help households transition to cleaner (i.e., less polluting) or more efficient stoves and mitigate these issues. Projects can also protect local biodiversity, reduce household fuel costs, generate jobs, and enhance public health. Due to their considerable development benefits, the Clean Development Mechanism (CDM) released its first methodology for cookstove projects in 2008. The VCM standards began accepting it shortly thereafter.[1] Since then, the VCM has mobilized critical finance towards the cooking challenge: 880 active clean cookstoves projects have issued more than 118 million credits globally.

Fundamentally, cooking is deeply cultural and personal, shaped by local food preferences, seasonal practices, available fuels and infrastructure, and longstanding traditions and habits. This makes these projects inherently complex to design, implement, and verify in a cost-effective, consistent, and high-quality manner – and those complexities laid the foundation for recent allegations of over-crediting and fraud in cookstove projects. Yet, led by improvements in digital technologies, accounting requirements, and monitoring, reporting, and verification (MRV) capabilities, they are continuing to deliver high-quality credits. To date, the Integrity Council on Voluntary Carbon Markets (ICVCM) has approved three active cookstove methodologies as aligned with their “Core Carbon Principles” (CCP), and Calyx Global, a ratings agency, recently gave its highest rating to a cookstoves project in Togo (a first for Calyx).

[1] When Verra accepted the CDM methodology, it allowed one project to ‘grandfather-in’ credits, beginning in 2004.

Project Activities and Stove Types

To earn credits, cookstove carbon projects help households use new stoves or fuels that produce fewer GHG emissions than the traditional methods. This occurs in one of two ways:

- Fuel switching: Providing a stove that uses a new, less emissions-intensive fuel compared to the original (e.g., switching from wood or charcoal to biogas or solar). These projects also improve stove efficiency.

- Fuel efficiency: Providing a higher-efficiency stove that requires less of the original fuel compared to the conventional stove (e.g., using a stove that still burns biomass, but burns less of it to cook the same amount of food).

Generally, cookstove projects operate in hundreds, thousands, or tens of thousands of households across a region and aggregate the climate benefits from each stove into one project. Project developers either provide households with one stove type or with several different stoves, depending on what is best for the project area. Broadly, there are six types of cookstoves, each with tradeoffs for health, cost, and efficiency (see Exhibit 1).

| Stove Type | Description | Cost & Infrastructure Needs | Health & Environmental Impacts* |

|---|---|---|---|

| Improved Biomass | Burns solid biomass fuels more efficiently than conventional stoves; includes solid wood, charcoal, and biomass pellets. | Stoves are generally cheap; fuel is relatively low-cost and available compared to other stoves. | Slows the rate at which wood and charcoal stoves contribute to forest degradation and indoor air pollution. Some stoves may meet WHO indoor air quality guidelines.* |

| Liquified Petroleum Gas (LPG)* | Uses a mix of propane and butane that is less emissions-intensive compared to coal, kerosene, and charcoal. | Stoves can have high upfront cost; requires specific infrastructure to distribute LPG cylinders. | Meets WHO definition of "clean" fuel. |

| Natural Gas* | Uses a fossil fuel mix mainly made of methane. | Stoves can have high upfront cost and require natural gas distribution infrastructure to scale. | Meets WHO definition of "clean" fuel. |

| Electric/ Solar Powered* | Includes hot plates, induction stove tops, electric pressure cookers, and rice cookers powered by grid-based electricity or directly by solar panels. | Stoves usually have a high upfront cost and can require electricity infrastructure to scale. | Meets WHO definition of "clean" fuel. |

| Biogas* | Uses gas produced from the decomposition of food waste, manure, and agricultural waste. | Setting up, operating and maintaining a biodigester can be expensive and challenging. | Meets WHO definition of "clean" fuel. |

| Bio-Ethanol* | Burns alcohol fuel made from crops. | Can be relatively low-cost to implement and fuel is generally accessible, but depends on region. | Meets WHO definition of "clean" fuel. Can contribute to food insecurity if feedstock is diverted from existing food supply chains. |

| * Note: These are based on the WHO's definitions of clean fuels and technologies for cooking, heating, and lighting that are safe for human health. The WHO definitions are built using the International Organization for Standardization (ISO) performance targets for air quality. Per the WHO, natural gas, LPG, electric, biogas, and ethanol stoves are considered "clean" for household health. Only biomass stoves that achieve an ISO rating of Tier 4 or 5 (out of 5) for PM2.5 emissions and Tier 5 of 5 for carbon monoxide emissions meet the WHO definition for clean. | |||

The "best" stove for a project is the one that households need and will actually use: that "best" is dependent on local conditions, including the needs of the cooks, the cost and availability of fuel, and availability of local infrastructure such as electricity or gas lines. Project developers should also use stoves that produce as little indoor air pollution as possible, given the needs and preferences of household cooks. To help project developers discern the most suitable type, the CCA maintains a catalogue of stove models based on relevant criteria, including ISO rating, price, fuel type, country, and performance metrics.

Main Greenhouse Gas Accounting Variables

The Essential fNRB Value

All cookstoves projects reduce the use of emissions-intensive fuels, either fossil fuels like coal or kerosene, or non-renewable biomass (see Box 1). Projects involving biomass burning stoves are issued credits based on the fraction of non-renewable (fNRB) biomass they use.

Box 1. Renewable vs Non-Renewable Biomass

The emissions impact of each biomass fuel (i.e., wood products or waste and residue from agriculture, animals, and wood production) depends on whether the biomass is renewable or non-renewable.

- Renewable biomass comes from sources that regenerate sustainably over time, such as well-managed woodlots or naturally replenishing forests. It is renewable if the biomass is harvested at the same rate it regrows, so the carbon released from burning is balanced by the carbon absorbed through regrowth.

- Non-renewable biomass (NRB) comes from sources where the rate of harvesting exceeds natural regrowth, such as from degraded or disappearing forests. In this case, burning biomass releases carbon into the atmosphere and accelerates forest degradation, biodiversity loss, and long-term ecosystem degradation.

Cookstove projects that reduce usage of biomass fuel only earn credits for the NRB use they displace. Developers base credit volumes off their calculation of the fraction of NRB (fNRB), or percentage of biomass fuel that is NRB (see Equation 1).

Equation 1

fNRB = NRB / (NRB + Renewable Biomass)

A high baseline fNRB value means most of the biomass fuel is non-renewable, so the project can avoid significant GHG emissions (and thus generate significant credits) if it reduces the use of non-renewable biomass during the project. A low baseline fNRB value means most of the fuel is renewable, so the project has a lower potential to reduce emissions. For those targeting biomass fuels, high-quality projects must accurately calculate the fNRB value for the baseline and project scenarios.

User households (also called “adoption rate”)

This is the number of households that adopt or install a new cookstove. It indicates how many traditional stoves could be displaced by the project. This variable is paired with stove usage to calculate how many emissions are being reduced by the project. Project developers generally gather data on stove adoption through surveys.

Stove usage

This measures how many households use a new cookstove and how much it is used for household cooking. This is paired with the adoption rate to estimate how many emissions were reduced as households switched to cooking with the new stove. Project developers use surveys or monitoring technology like stove use monitors (SUMs) to confirm stove usage.

Fuel consumption

This is how much fuel a household uses with the traditional stove and the new one. The more efficient a stove is, the less fuel it consumes to heat the same amount of food. Fuel consumption can be influenced by stove stacking and rebound effects:

- Stove stacking: Stove stacking occurs when a household uses both the project cookstove and their old, conventional stove. Historically, not all cookstove methodologies have accounted for stacking, but the Kitchen Performance Test (KPT) (see The Three Stove Performance Tests) can capture stacking.

- Rebound effect: This occurs when the project stove makes cooking cheaper, faster, or more efficient, such that the household ends up using their stove more than they did before. This can unintentionally result in the household consuming more fuel than it did before the project — and can reduce the expected GHG emission reductions from the new stove. Historically, cookstove methodologies struggled to account for rebound, but some CCP-approved methodologies require KPTs that account for it.

The Three Stove Performance Tests

Cookstove methodologies generally require developers to use one or more performance tests to monitor and measure these key variables and optional parameters, such as emissions of harmful air pollutants. Each test has tradeoffs among the ease of implementation, costs, and accuracy.

Laboratory Test (previously: Water Boiling Test)

In a laboratory test, a technician follows a standard test sequence in a closed environment to measure how much fuel and time a stove needs to heat water. The one designed for cookstoves is ISO 19867 – it measures thermal efficiency, PM2.5 emissions, and CO emissions. This test replaced the water boiling test (WBT) in 2018. Laboratory testing is easily repeatable, inexpensive, and useful for comparing stoves’ thermal efficiency in standardized conditions. However, it does not accurately represent real-world conditions or cooking behaviors and can overestimate fuel savings.

Controlled Cooking Test

A controlled cooking test (CCT) measures the specific fuel consumption of a given stove, where local cooks use a standardized recipe (usually a local one) in a controlled setting. If project developers use meters, a CCT can help them estimate the baseline fuel consumption. CCTs are generally more accurate at estimating the fuel consumption from real cooking conditions than the laboratory or WBT tests.

Kitchen Performance Test

A kitchen performance test (KPT) measures the total fuel consumption of a household. Over a few days or a week, technicians measure how much fuel a cook uses for all cooking devices in the household (i.e., both project stoves and conventional stoves) under typical conditions. Project developers conduct KPTs in a sample of participating households, either through a paired sample study[1] or a cross-sectional study.[2] KPTs are one of the most widely accepted and accurate ways of determining real-world fuel use, but are labor and time-intensive to complete.

[1] In a paired sample study, project developers track the same household before and after introducing the improved stove.

[2] In a cross-sectional study, project developers track one group that uses conventional stoves and a different group that uses the improved stove.

Market Snapshot

Cookstove crediting projects have issued credits since 2004 — and are one of the largest crediting types on the market, both by volume of credits issued and number of individual projects. As of August 2025, cookstove projects have issued more than 181 million credits (see Exhibit 2), accounting for 7.6% of all credits issued by the VCM. To date, Gold Standard has issued over 122 million cookstove credits (67.5% of market share), while VCS has issued over 58 million credits (32.5% of market share). Cookstoves projects primarily occur in LMICs and have been implemented in 63 different countries. Nearly 70% of all credits issued originate in Sub-Saharan Africa, which is likely due to high regional fNRB values that create an opportunity for large credit volumes. Roughly 1 in every 3 projects, or 34%, occur in Kenya, Uganda, or Ghana. Credit issuances are also high across Asia, with 9% of total issuances coming from India (see Exhibit 2).

| Geographic Region* | Total Credits Issued | Percentage of Credits Issued |

|---|---|---|

| Sub-Saharan Africa | 124,417,687 | 68.6% |

| Southern Asia | 26,435,280 | 14.6% |

| South-Eastern Asia | 13,484,494 | 7.4% |

| Latin America and the Caribbean | 9,177,782 | 5.1% |

| Eastern Asia | 7,267,564 | 4.0% |

| Northern Africa | 368,399 | 0.2% |

| Oceania | 180,540 | 0.1% |

| Global | 181,331,746 | 100% |

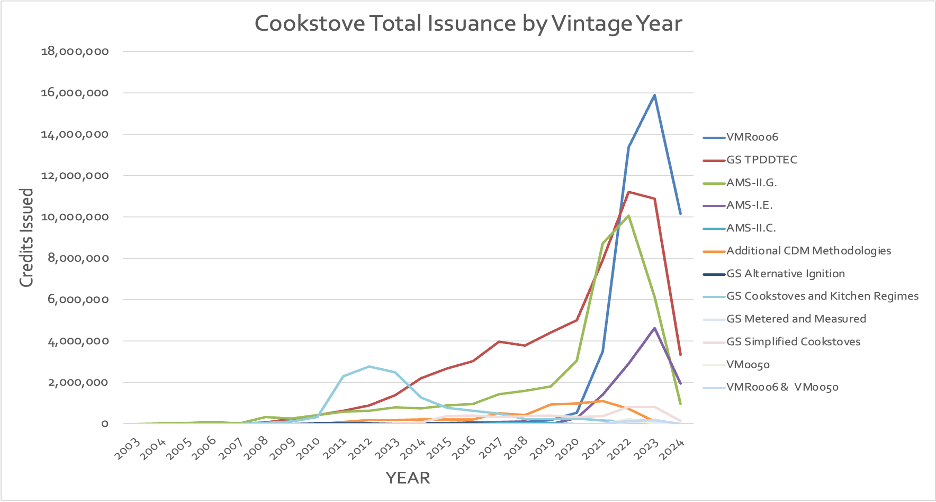

Early Methodologies

Since 2008, 15 methodologies from the CDM and VCM registries have supported clean cookstove crediting projects, but three have issued 80% of all credits (see blue rows in Exhibit 3). A detailed history of these 15 methodologies and their evolution is in Appendix 2.

The three methodologies that are responsible for 80% of cookstove credit issuances are:

- CDM’s AMS-II.G: Applies broadly to energy efficiency projects and became active in 2008. Its 14th version is still active. Verra accepted projects using the latest AMS-II.G methodology from 2008 to 2023. Gold Standard still accepts projects using this methodology.

- Verra’s VMR0006: Verra adapted CDM’s AMS-II.G to create this methodology, which targets energy efficiency activities in thermal applications (i.e., cookstoves, ovens, and dryers). It was released in September 2020 and was active until October 2024, when it was replaced with VM0050. Many CDM projects transferred to this methodology while it was active.

- Gold Standard’s Technologies and Practices to Displace Decentralized Thermal Energy Consumption (TPDDTEC): Released in 2011, this covers energy efficiency activities for thermal appliances — including, but not limited to, cookstoves. It has issued 34% of all cookstove credits. Version 4 was released in July 2021 and is the active version.

| Methodology | Total Credits Issued | Total Credits Retired | Crediting Projects | Registered Projects | ||

|---|---|---|---|---|---|---|

| Number | % of Total | Number | % of Total | |||

| Legacy and Inactive Methodologies | ||||||

| AMS-I.C. | 5,338,582 | 2.9% | 2,635,254 | 3.0% | 18 | 19 |

| AMS-I.E. | 11,504,715 | 6.3% | 651,188 | 0.8% | 10 | 37 |

| AMS-II.G. | 39,537,619 | 21.8% | 14,855,629 | 17.1% | 308 | 441 |

| Additional CDM Methodologies* | 826,828 | 0.5% | 627,905 | 0.8% | 6 | 6 |

| GS Cookstoves and Kitchen Regimes | 12,337,945 | 6.8% | 11,417,652 | 13.2% | 19 | 25 |

| GS Alternative Ignition | 199,262 | 0.1% | 197,825 | 0.2% | 13 | 13 |

| VMR0006 | 44,313,573 | 24.5% | 15,209,066 | 17.5% | 64 | 212 |

| Subtotal | 114,058,524 | 62.9% | 45,594,519 | 52.6% | 438 | 753 |

| Updated, New and Forthcoming Methodologies | ||||||

| GS Metered and Measured | 130,828 | 0.1% | 6,773 | <0.1% | 8 | 62 |

| GS Simplified Cookstoves | 4,460,027 | 2.5% | 2,418,156 | 2.8% | 244 | 337 |

| GS TPDDTEC | 61,109,665 | 34.3% | 38,764,809 | 44.6% | 186 | 424 |

| VM0050 | 240,406 | .1% | 29,485 | <0.1% | 2 | 9 |

| VM0050 & VMR006 | 332,296 | .2% | 2,690 | 0% | 2 | 2 |

| CLEAR | 0 | 0% | 0 | 0% | 0 | 0 |

| Subtotal | 66,273,222 | 37.1% | 41,203,913 | 47.4% | 442 | 834 |

| GRAND TOTAL | 180,331,746 | 86,798,432 | 880 | 1,587 | ||

| Note: Some developers use more than one methodology as they are transferring from one registry to another, or so that they can implement more than one stove type. This is rare, impacting only 7 registered projects and 825,836 credits. *Additional CDM methodologies include projects under AMS-II.C, AMS-III.B.G., and projects filed jointly under AMS-II.C. & AMS-II.G and AMS-III.B.G. & VMR0006. Source: Barbara K Haya, Tyler Bernard, Aline Abayo, Xinyun Rong, Ivy S. So, Micah Elias. (2025). Voluntary Registry Offsets Database v2025-08, Berkeley Carbon Trading Project, University of California, Berkeley. Retrieved from: https://gspp.berkeley.edu/berkeley-carbon-trading-project/offsets-database. See the Appendix for more information on how we used this data. |

||||||

These early cookstove methodologies, two of which are inactive or fading in use (see Exhibit 3), dominated the market because they were the first available and thus quickly became areas of internal expertise. Defined by their simplicity and flexibility, these methodologies encompassed a broad range of energy efficiency activities (not just cookstoves) and offered streamlined requirements that made them less labor- and time-intensive for developers to implement. However, this flexibility allowed project developers to make fairly generous assumptions about the key accounting parameters discussed earlier—such as fuel use, stove adoption, and fNRB—that did not always reflect actual project performance and ultimately led to allegations of over-crediting and greenwashing. These allegations brought public scrutiny to the integrity of cookstove projects.

Cookstoves Projects Face Public Scrutiny

In 2023, researchers at the University of California, Berkeley published research, and subsequently an article in Nature Sustainability, that showed how simplified accounting practices had enabled over-crediting in cookstove projects, including:

- Inflating the fNRB value: Projects were incorrectly calculating the fNRB value of biomass burned in the project area, which exaggerated the emissions a clean cookstoves project saved. These fNRB numbers were based on poor underlying data and/or default values that were too high for their project region.

- Inaccurately estimating fuel consumption and stove usage: Projects were found to have poor estimations of fuel consumption and stove usage in both the baseline and project scenarios that were based on national or regional estimates or surveys that were not representative of actual household habits.

- Underestimating stove stacking: Projects overlooked or underestimated the impact of using traditional stoves after project interventions, ultimately overestimating the project's climate benefit.

The research was summarized in a Guardian article, which brought public criticism to the credit type. Cookstove stakeholders, including Gold Standard, Verra , and a consortium of other industry participants, pushed back. In a set of letters, they pointed out shortcomings in the research methodology, raised concerns about conflicts of interest with the research team, and highlighted ongoing efforts among cookstove stakeholders to update and strengthen availability methodologies. Specifically, they criticized the Nature article for an unsubstantiated assumption that the results in the academic literature are representative of "the design, target populations, and performance of cookstove projects" in the VCM and for flaws in how the researchers conducted their sampling and Monte Carlo Analysis. These letters reiterated that cookstove stakeholders were actively working to improve the standards, data, and overall quality of cookstove projects, including through the Clean Cooking and Climate Consortium's (4C's) push to develop the CLEAR methodology.

Concerns over the efficacy of cookstoves projects were compounded when it became public that the project developer C-Quest Capital (CQC) allegedly provided misleading cookstove survey data to the VCS. In 2024, a VCS investigation into 26 CQC projects found that CQC had been issued over 5 million more credits than the projects delivered. The VCS program cancelled these credits. Eventually, the US Attorney's Office for the Southern District of New York announced criminal charges against the ex-CEO and other individuals employed by CQC.[1] The risk of this kind of fraud is not unique to cookstove projects, but does highlight the importance of increased transparency.

These public controversies had a notable effect on demand for cookstove credits. Cookstove credit issuances grew rapidly from 2019 to 2023, then sharply declined in 2024 (see Exhibit 4).

Exhibit 4. Total Cookstove Credit Issuance on the VCM by Methodology

New Cookstoves Methodologies Aim to Address Quality Concerns

While the public scrutiny of VCM cookstoves projects is a relatively recent phenomenon, cookstove experts and industry leaders have long been iterating on the methodologies to best capture the impact of these projects – and the lessons learned from implementation. This culminated in three main reforms from Gold Standard, Verra, and the Clean Cooking Alliance (CCA) in recent years, and yielded four leading methodologies (see Exhibit 5).

Specifically, Gold Standard

- retired its Methodology for Improved Cookstoves and Kitchen Regimes,

- updated its TPDDTEC methodology (now version 4), and

- released a new methodology: The Methodology for Metered and Measured Energy Cooking Devices.

Meanwhile, Verra

- released VM0050, a consolidated cookstove methodology,

- retired VMR0006, and

- stopped accepting the majority of CDM cookstove methodologies.

In parallel, the CCA-led 4C collaboration developed a new cookstove methodology, reflecting the latest best practices, and released a draft for public consultation in 2025. The Comprehensive Lowered Emissions Assessment and Reporting (CLEAR) Methodology for Cooking Energy Transitions aims to be the universal cookstove methodology for the VCM and under Article 6.2 of the Paris Agreement. It is anticipated to set a high bar for project MRV and accurate cookstove accounting.

In early 2025, the ICVCM conditionally approved three cookstove methodologies — the GS TPDDTEC Methodology v4.0, GS Metered and Measured Methodology v1.2, and VCS VM0050 v1.0 — for the CCP label (Exhibit 5). The CCP label is viewed as an endorsement of the rigor of each methodology's quantification practices, but only applies if projects use the current best practices for fNRB values (see the section on GHG Accounting in Quality Risks and Mitigation Measures).

| Standard | Methodology | Status | Eligible Activities |

|---|---|---|---|

| Gold Standard | GS Methodology for Metered and Measured Energy Cooking Devices, v1.2 | Active since 2022, CCP-approved | Fuel Switching or Fuel Efficiency: all fuels |

| Gold Standard | GS Reduced emissions from cooking and heating: Technologies and Practices to displace decentralized thermal energy consumption (TPDDTEC), v4.0 | Active since 2021, CCP-approved | Fuel Efficiency: all fuels |

| Verified Carbon Standard | VM0050 Energy Efficiency and Fuel-Switch Measures in Cookstoves, v1.0 | Active since 2024, CCP-approved | Fuel Switching or Fuel Efficiency: all fuels |

| Submitted to Gold Standard and Verra (Nov 2024) and UNFCCC (May 2025) | Comprehensive Lowered Emissions Assessment and Reporting (CLEAR) Methodology for Cooking Energy Transitions | Public consultations closed in 2024 (4C) and 2025 (UNFCCC) | Fuel Switching or Fuel Efficiency: all fuels |

Our risk analysis focuses on the four methodologies in Exhibit 5. While the CCP labels are promising, projects have just started issuing credits using these methodologies, and it remains to be seen how the market will judge the quality of the credits. The forthcoming CLEAR methodology is primed to represent the industry's best practices. It is anticipated that many project developers will prioritize a shift to this methodology. If that happens, future cookstove VCM projects would have a lower risk profile.

[1] Jules Kortenhorst was previously the CEO of RMI. Following his departure from RMI, he was appointed CEO of CQC after CQC's ex-CEO stepped down due to the fraud investigation.Quality Risks and Mitigation Measures

Cookstoves have gone through ebbs and flows of scrutiny and improvement, with historic links to over-crediting. Since their inception, standards have responded to quality concerns by introducing stricter monitoring requirements, updated emissions factors, and improved protocols to derive fNRB values. While these changes have improved market-wide quality, individual project due diligence is still essential.

This analysis summarizes the risk severity and prevalence for key quality indicators in the updated Gold Standard, the VCS, and CLEAR methodologies. For more information about how we assess risk, see Appendix 3.

| Quality Criteria | Risk Severity | Prevalence |

|---|---|---|

| GHG Accounting | Medium Concern | Common |

| Additionality | Low Concern | Uncommon |

| Leakage | Low Concern | Uncommon |

| Permanence | Low Concern | Uncommon |

| Monitoring, Reporting and Verification (MRV) | High Concern | Very Common |

| Social and Environmental Safeguards | Low Concern | Uncommon |

GHG Accounting – Medium Concern, Common Prevalence

Overestimating fNRB leads to over-crediting: The over-crediting issues arose from cookstoves projects using inflated fNRB values, often due to inaccurate or outdated fNRB data as allowed by the legacy methodologies. A high fNRB value is not a red flag for a project, but the developer must back it up with robust data that demonstrates the amount of NRB they are displacing. Best practice is to use a locally validated fNRB value, based on a thorough geospatial analysis using the UNFCCC's peer-reviewed MoFuSS (Modeling Fuelwood Sustainability Scenarios) model. CCP approval is conditional on certain conditions, described below. The four methodologies have the following requirements for determining the fNRB value (Exhibit 7):

| Standard | Methodology | Permitted fNRB Approaches |

|---|---|---|

| Gold Standard | GS Methodology for Metered and Measured Energy Cooking Devices, v1.2 | Apply UN values (e.g., from MoFuSS), use TOOL30, or apply conservative 30% value |

| Gold Standard | GS Reduced emissions from cooking and heating – technologies and practices to displace decentralized thermal energy consumption (TPDDTEC), v4.0 | Apply UN values (e.g., from MoFuSS), use TOOL30, or apply conservative 30% value |

| Verified Carbon Standard | VM0050 Energy Efficiency and Fuel-Switch Measures in Cookstoves, v1.0 | Apply UN values (e.g., from MoFuSS), use TOOL30, or apply conservative 30% value |

| Submitted to Gold Standard and Verra in Nov 2024 and UNFCCC in May 2025 | Comprehensive Lowered Emissions Assessment and Reporting (CLEAR) Methodology for Cooking Energy Transitions | Use MoFuSS to derive fNRB |

The market is moving to address inflated fNRB values. TOOL30 will be withdrawn in 2026, and the ICVCM granted CCP approval to these methodologies on the condition that developers either use a conservative 30% as the fNRB value or derive one from MoFuSS. CCA is developing an online version of MoFuSS to allow users to upload their own input data and run the model on a cloud-based server, which will increase the tool's accessibility. Some projects have continued to use TOOL30, despite the industry push to adopt MoFuSS.

Stove rebound can lower expected net GHG reductions: If the project developer fails to detect and account for the rebound effect, they risk over-crediting their project. There are two active debates among experts: whether methodologies should account for rebound and the significance of the rebound effect on project emission reductions.

Project developers can capture any rebound by conducting KPTs in the baseline and project scenario (see the three stove performance tests) to detect changes in total household fuel use. However, not all methodologies require project developers to conduct KPTs, which can be time and resource-intensive, so rebound can go unaccounted. See Exhibit 9 in the MRV section for information on updated monitoring requirements.

Additionality - Low Concern, Uncommon Prevalence

Additionality is not a key risk for cookstove projects: Improved and clean cookstoves save time, labor, and money, and improve household air quality. While these benefits can incentivize adoption of a cleaner cookstove without carbon finance, most households cannot access modern cookstoves due to cultural practices, high costs, limited knowledge, and poor energy infrastructure. As such, projects can be required to complete a thorough additionality assessment, including a regulatory surplus, a common practice analysis, and a barrier analysis or investment analysis to mitigate additionality risks (see Exhibit 8).

| Methodology | Regulatory Surplus | Positive List | Common Practice/ Market Penetration | Financial Viability/ Investment Analysis | Barrier Analysis |

|---|---|---|---|---|---|

| TOOL1* | R | R | O | O | |

| TOOL19* (Micro-scale projects) | R | R | |||

| TOOL21* (Small-scale projects) | R | R | |||

| VM0050 | R | O | O | O | O |

| CLEAR | R | R | O | R | |

| R = required; O = available option, at least one required. *Gold standard requires projects to apply the methodology outlined in either Tool1, Tool19, or Tool21. | |||||

Leakage – Low Concern, Uncommon Prevalence

Experts do not believe emissions leakage is a significant risk for cookstoves projects. However, emissions leakage could occur when the fuel saved by the project is used by someone else — for example, when surplus charcoal gets used by other households to cook. Since this kind of leakage is hard to quantify, all analyzed methodologies require or suggest project developers apply a conservative discount (commonly between 2% and 5%) for leakage.

Permanence – Low Concern, Uncommon Prevalence

Cookstoves projects that preserve forest stocks by reducing NRB use could face permanence risks. If the forests claimed as protected are later lost, such as from logging or wildfires, then the emissions benefit of saving those trees is not permanent. While developers could, in theory, continuously track biomass sources to reduce this risk, some experts view this as impractical due to the technical difficulty and associated costs of such tracking and the diffused sources of biomass fuel for households.

Instead, permanence is managed by using high-quality, regularly updated fNRB values. This ensures credits are issued only for biomass that is unlikely to regenerate without the project. An assessment by Calyx concluded their cookstoves projects have a low risk of non-permanence, underscoring that this is not a major quality risk.

Monitoring, Reporting and Verification (MRV) – High Concern, Very Common Prevalence

Numerous behavioral and contextual factors influence household cooking, each of which requires complicated monitoring practices to accurately estimate baseline and project emissions. All monitoring approaches provide project developers with tradeoffs in cost, time, labor, and accuracy. For example, direct and continuous monitoring of fuel consumption greatly improves the accuracy of the emissions calculations, but is not economically or logistically feasible for all project types. The MRV nuances of key accounting parameters are as follows:

Stove adoption and usage rates are variable

Households can install a new stove, but that doesn't guarantee it will be used as projected. Long-term usage depends on food preferences, fuel availability, the division of labor within a household, and the season. Thus, project developers need to use the best available data to assess actual stove usage. This data can be collected through door-to-door surveys, stove use monitors, field trainings, or awareness campaigns, all with their own strengths in the appropriate project context.

Each monitoring approach has tradeoffs in costs, resources, and methodology requirements — so it needs to be tailored to fit the project. Door-to-door surveys, for example, are widely used but need to be carefully designed to reflect the diversity and sufficient sample size of participating households. Stove use monitors (SUMs) are used to improve and validate survey findings, but can be costly to deploy and operate and are not applicable to all stove types.

For example, TPDDTEC (version 4) caps the acceptable adoption rate depending on the monitoring methods:

- projects using SUMs may count over 90% of households,

- those implementing field trainings and awareness campaigns can count up to 90% of households, and

- those that only use surveys can count up to 75% of households.

Developers need accurate fuel consumption data to claim real emissions reductions

Baseline and project stove emissions are based on an estimate of household fuel consumption and the emission factor for each fuel type. Fuel consumption changes based on fuel and stove model, the season, and individual cooking habits. Project developers can use continuous metering, SUMs, survey or literature data, kitchen performance tests, or fuel sales data to collect this information.

The analyzed methodologies have a mix of requirements for which monitoring approach can be used to calculate baseline and project fuel consumption (see Exhibit 9).

| Standard | Methodology | Stove Adoption/ Users | Baseline Fuel Consumption | Project Fuel Consumption |

|---|---|---|---|---|

| Gold Standard | GS Methodology for Metered and Measured Energy Cooking Devices, v1.2 | Not required separately from the continuous monitoring | Back-calculated based on project usage via continuous fuel monitoring; fuel type based on literature or survey data | Continuous fuel consumption monitoring via data loggers or fuel sales data |

| Gold Standard | GS Reduced emissions from cooking and heating – technologies and practices to displace decentralized thermal energy consumption (TPDDTEC), v4.0 | Surveys required, SUMs optional | Conservative default value, literature derived data, or KPT | KPT |

| Verified Carbon Standard | VM0050 Energy Efficiency and Fuel-Switch Measures in Cookstoves, v1.0 | Surveys required, SUMs optional | Conservative default value or KPT | Continuous stove monitoring or KPT |

| Submitted to Gold Standard and Verra in Nov 2024 and UNFCCC in May 2025 | Comprehensive Lowered Emissions Assessment and Reporting (CLEAR) Methodology for Cooking Energy Transitions | Surveys required, SUMs optional | KPT or back-calculated based on project usage via continuous fuel monitoring, or suppressed demand | Continuous fuel monitoring via data loggers or fuel sales data or KPT |

BCTP recommends continuous fuel use monitoring (through metering or fuel purchase data) as the most robust option to estimate fuel consumption. If continuous monitoring is not feasible, KPTs can also produce accurate estimates of fuel consumption.

Stove stacking can reduce project impact

Households stack stoves when the improved stove cannot meet all their cooking needs, but stove stacking dilutes the emissions impact of a cookstove project. Project developers can take steps to reduce stacking:

- providing stoves with adequate cooking capacity to meet household needs (e.g., multiple burners),

- ensuring each household has a stove that is compatible with their cooking preferences, or

- incentivizing participants to stop using or discard their old stove, such as through stove buy-back programs, rewards, and behavior change campaigns.

The four methodologies in this analysis largely account for stacking — and KPTs are the most accurate approach, though they may be impacted by the Hawthorne effect (see below).

Surveys and performance tests are subject to the Hawthorne effect

The Hawthorne effect occurs when people change their behavior because they are being monitored. Some studies have found that cooks increase their use of the project stove and reduce the use of other stoves when being observed, such as during a KPT; others have not detected a significant Hawthorne effect.

Developers can mitigate for the Hawthorne Effect by complementing KPTs or other direct observations with additional data collection, such as SUMs, to capture how cooks use stoves outside of direct observations. Fuel purchase records or data loggers can also mitigate the Hawthorne effect. The BCTP recommends that project developers reduce usage rates by 35% to account for a potential Hawthorne effect, and CLEAR requires a deduction of 25% for the Hawthorne Effect if SUMs are not used.

Uncertainty in sampling is a ubiquitous challenge for cookstove projects: Sampling collects data from a subset of participating households to estimate key parameters like stove adoption, usage, and fuel consumption for all households. Developers use sampling because it is often impractical and cost-prohibitive to collect data from every household in the project. However, it is difficult to get sampling right.

A poorly designed sample risks introducing bias or fails to capture the nuances among households due to diverse habits, cultures, geography, and fuel use patterns that can cause over- or under-crediting. Unfortunately, cookstove project sample sizes are often small; one BeZero analysis found that the majority of cookstove projects monitor less than 1% of all stoves distributed. This can result in sampling that is unrepresentative of the realities inside participating households, which can skew the project's understanding of stove adoption and fuel consumption.

Buyers should look for projects that implement sampling best practices to reduce uncertainty, improve confidence, reduce the margin of error, and increase accuracy:

- Adequate sample size: Ensure the sample assessed is large enough to capture the full range of differences across households. Larger samples generally reduce uncertainty in data.

- Representative sample selection: Ensure the sample reflects the diversity of participating households in their geography, cooking practices, household size, fuel types, and stove types. Random sampling or stratified random sampling can reduce bias in sample selection.

- Monitoring consistency: Ensure sampling is done in the same way during the baseline and project monitoring periods.

- Quality control and transparency: Ensure sampling procedures are clearly and transparently documented, checked for errors and inconsistencies, and audited by a third party, such as a VVB.

Each methodology sets its own requirements for sample size, sampling procedure, uncertainty deductions, and the confidence and precision levels. While robust "research-grade" results show a 95% confidence interval, this standard creates higher monitoring costs (i.e., time and labor) and may require a level of intrusion into the lives of participating households that is not acceptable. As a result, the four methodologies require a 90% confidence interval.

Buyers should look for projects that implement scientifically rigorous sampling practices, such as stratified sampling, where applicable, and that aim for the largest samples possible, while balancing the project developer's time, labor, cost, geographic location, and other constraints. While developers can avoid sampling by directly measuring fuel consumption of all project devices, this is not always economically or logistically possible for all stove types.

Social and Environmental Safeguards – Low Concern, Uncommon Prevalence

Cookstove projects can offer many socio-environmental benefits, including:

- Time, cost, and labor savings: Reduced time spent on fuel collection (e.g., charcoal, wood, and other traditional fuels), coupled with improved cooking efficiency, allows households to spend less time and money on cooking and frees up resources for other work, rest, or education.

- Health improvements: Improved and clean stoves reduce indoor air pollution, lowering the risk of respiratory and cardiovascular disease.

- Climate benefits: Project stoves reduce emissions of intense pollutants like black carbon, PM2.5, and carbon monoxide – yielding additional, and often under-emphasized, climate impacts.

- Accelerating economic growth: Clean cooking supports local employment in manufacturing, operations, sales, monitoring, distribution, and maintenance.

- Women's empowerment: Because women are primarily the household's cooks, or the ones tending to the stoves, improved stoves reduce their exposure to harmful pollutants and reduce household labor burdens.

- Forest protection and increased ecosystem health: Lower demand for charcoal and/or wood helps curb forest degradation, conserve biodiversity, and protect ecosystem services (e.g., water purification, flood protection, pollination services).

However, projects may also encounter the following social risks, which can be mitigated with good project design:

-

Providing improper stoves for the household context

Stoves that don't actually match household needs or preferences have lower adoption and satisfaction rates, ultimately undermining the co-benefit impacts of a project. Co-designing projects with participating households to provide stoves that best suit their needs and context can mitigate this risk. Some developers sell and/or provide financing for project stoves to promote project buy-in. -

Incentivizing the use of sub-standard stoves

The BCTP recommends that cookstoves meet the WHO's standards of Tier 4 for particulate matter and Tier 5 for carbon monoxide. However, meeting these standards is not possible for all projects, either due to the lack of fuel access and energy infrastructure needed for the "cleanest" stove types or to socio-cultural factors that yield a strong preference for biomass fuels. In these cases, improved biomass stoves can be a quality interim solution. -

Inequitable compensation for households taking part in the project

Inadequate or unclear benefit sharing can exacerbate inequities and erode trust in a project. Project developers must have the informed consent of all project participants, and diligent buyers can look for transparent and robust benefit sharing (e.g., subsidizing stoves or fuel, or non-monetary support like training and education). -

Exclusion of vulnerable groups from participation

Focusing on easily accessible and/or wealthier households can exacerbate inequality in both the project area and its operations, skewing project impacts. All projects should conduct a thorough stakeholder assessment and ensure they approach all potential participants – including remote households, minority communities, and those with relatively lower education - in an equitable way.

The active cookstove methodologies give limited attention to co-benefit monitoring, but diligent buyers may choose to closely assess projects for community engagement and look for projects that monitor social impacts – including those that receive additional certifications, such as the Climate, Community and Biodiversity (CCB) label.

Prospects Moving Forward

Cookstove credits have evolved significantly since their inception into the VCM, with recent methodological improvements tightening requirements for surveys, fNRB calculations, and fuel consumption monitoring to reduce the risk of over-crediting. The forthcoming CLEAR cookstove methodology is likely to raise the bar even higher for future cookstoves credits and accelerate the market towards alignment with the ICVCM’s CCP label.

Projects using CLEAR and the three CCP-approved methodologies will likely find increased support from buyers as they implement best practices like continuous monitoring, robust KPTs, and/or large sample sizes. These projects have the possibility of facing higher implementation costs for developers, which could price smaller projects out of the market. However, non-metered projects can be high quality, as evidenced by Calyx Global’s first-of-its-kind “Tier 1” rating for the Aborify Cookstoves Togo project. As of November 2025, Gold Standard is conducting public consultations on a methodology tool for the digital monitoring of cookstoves projects, with expectations it will be available in early 2026. This tool could influence how the market approaches digital MRV of KPTs, stove usage, and sales. With a project type that hinges on such complex changes to human behavior, project-level due diligence must be conducted.

Despite progress, clean cooking remains inaccessible for 2.3 billion people. Carbon credit financing continues to be a critical source of support, but its future depends on developers’ ability to implement best practices and buyers’ willingness to pay for quality. Host country support (e.g., governments that include cookstove credits as an accepted credit type under the Paris Agreement’s Article 6 mechanisms) will be instrumental to scaling success. If conducted responsibly, these projects can help LMICs accelerate cleaner cooking transitions and transform the reputation of cookstove projects from potentially risky to credible, scientifically sound emission reduction credits.

Appendices

Appendix 1: Acronym List

4C – Clean Cooking and Climate Consortium

BCTP – Berkeley Carbon Trading Project

CCA – Clean Cooking Alliance

CCP – Core Carbon Principles

CCT – Controlled Cooking Test

CLEAR – Comprehensive Lowered Emissions Assessment and Reporting (Methodology)

CDM – Clean Development Mechanism

FNRB – Fraction of Non-Renewable Biomass

GHG – Greenhouse Gas

GS – Gold Standard

ICVCM – Integrity Council for the Voluntary Carbon Market

IPCC – Intergovernmental Panel on Climate Change

ISO – International Organization for Standardization

KPT – Kitchen Performance Test

LMICs – Low- and Middle-Income Countries

LPG – Liquified Petroleum Gas

MoFuSS – Modeling Fuelwood Saving Scenarios

MRV – Monitoring, Reporting and Verification

NRB – Non-Renewable Biomass

SUM – Stove Use Monitor

TPDDTEC – Technologies and Practices to Displace Decentralized Thermal Energy Consumption (Methodology)

UN – United Nations

UNFCCC – United Nations Framework Convention on Climate Change

VCM – Voluntary Carbon Market

VCS – Verified Carbon Standard

WBT – Water Boiling Test

WHO – World Health Organization

Appendix 2: A Detailed History of Cookstove Methodologies

The earliest methodologies came from the Clean Development Mechanism (CDM) in 2008 and were broadly applicable to reducing emissions from household energy use, including cookstoves. Both Gold Standard and the VCS initially accepted registrations under the CDM methodologies, and the first VCM projects used CDM methodology AMS-II.G, designed broadly for household energy projects but frequently adapted by developers for cookstoves. Around the same time, Gold Standard began issuing credits under their own protocol, "Methodology for Improved Cookstoves and Kitchen Regimes." The VCS started issuing credits under the CDM methodology AMS-II.G in 2010. The VCS then adapted the AMS-II.G protocol into its own methodology, VMR0006, which was approved in September 2020 (Exhibit A1).

While these methodologies provided an initial framework for cookstove project accounting, they sometimes left room for project developers to make significant assumptions about key parameters like fuel use, stove adoption, and fNRB, which opened the door for over-crediting. This was not deliberate: standard-setters have worked to apply the latest scientific knowledge and a thorough peer-review process to their protocols, but at times, best practice evolved quicker than the methodologies were updated.

Historically, most cookstove credits come from Gold Standard's TPDDTEC methodology and the VCS's VMR0006 methodology (adapted from CDM AMS-II.G), which together are responsible for nearly 60% of all cookstove credits issued to date. A third major contributor is the CDM methodology AMS-II.G. These three methodologies likely dominated the early cookstove market for the following reasons:

- Early adoption: These methodologies were some of the first available, so cookstove project developers built internal expertise and MRV processes for them early on.

- Simplicity and flexibility: The three methodologies were all broad in activity scope, making them adaptable across stove types and geographies. These methodologies also initially had streamlined MRV requirements, making them less labor and time intensive for developers to implement.

- Favorable assumptions: Older versions of these methodologies allowed developers to apply stove efficiency numbers from WBTs that were unrealistic, fNRB values that were uncertain, and MRV practices that did not adequately capture stove stacking, rebound, or fuel consumption. Not all developers were simply attempting to game the system; rather, the scientific understanding of how behavioral factors impacted emissions reductions and how best to monitor and mitigate these impacts was evolving.

Exhibit A1 provides a summary of all active and inactive cookstove crediting methodologies under which projects have registered with Gold Standard or the VCS. Exhibit A2 summarizes the market activity of all active and inactive cookstove methodologies.

| Standard | Methodology | Status | Eligible Activities |

|---|---|---|---|

| CDM (accepted by Gold Standard and VCS as of 2025) | AMS-I.C. Thermal energy production with or without electricity, v22.0 | Active since 2022, CCP assessment not complete | Fuel switching: fossil fuels to renewable energy |

| CDM (accepted by Gold Standard as of 2025) | AMS-I.E. Switch from non-renewable biomass for thermal applications by the user, v14.0 | Active since 2025, denied CCP label, no longer accepted by VCS as of 2025 | Fuel switching: NRB to renewable energy |

| CDM (accepted by Gold Standard as of 2025) | AMS-I.I. Biogas/biomass thermal applications for households/small users, v7.0 | Active since 2024, denied CCP label, no longer accepted by VCS as of 2025 | Fuel switching: fossil fuels to renewable biomass or biogas |

| CDM (accepted by Gold Standard as of 2025) | AMS-I.K. Solar cookers for households, v1.0 | Active since 2012, no longer accepted by VCS as of 2025 | Fuel switching: fossil fuels or NRB to solar |

| CDM (accepted by Gold Standard and VCS as of 2025) | AMS-II.C. Demand-side energy efficiency activities for specific technologies, v16.0 | Active since 2023 | Fuel efficiency: all fuels |

| CDM (accepted by Gold Standard as of 2025) | AMS-II.G. Energy efficiency measures in thermal applications of non-renewable biomass, v14.0 | Active since 2025, denied CCP label, no longer accepted by VCS | Fuel efficiency: NRB stoves |

| CDM (accepted by Gold Standard as of 2025) | AMS-III.BG. Emission reduction through sustainable charcoal production and consumption, v5.0 | Active since 2025, no longer accepted by VCS | Fuel switching: NRB charcoal to renewable charcoal |

| Gold Standard | GS Methodology for Improved Cookstoves and Kitchen Regimes, v2.0 | Inactive, replaced by TPDDTEC | Fuel efficiency: all fuels |

| Gold Standard | GS Methodology for the Introduction of an Alternative Ignition Technique as Measure to Improve the Energy Efficiency of Domestic Coal Fires | Inactive as of 2025 | Fuel efficiency: coal |

| Gold Standard | GS Simplified Methodology for Clean and Efficient Cookstoves | Active since 2022, denied CCP label | Fuel Efficiency: wood or charcoal |

| VCS | VMR0006 Energy Efficiency and Fuel Switch Measures in Thermal Applications, v1.2 | Inactive as of 2025, replaced by VM0050 | Fuel switching (NRB to renewable biomass) or fuel efficiency (NRB) |

| Methodology | Total Credits Issued | Total Credits Retired | Crediting Projects | Registered Projects | ||

|---|---|---|---|---|---|---|

| Number | % of Total | Number | % of Total | |||

| Legacy and Inactive Methodologies | ||||||

| AMS-I.C. | 5,338,582 | 2.9% | 2,635,254 | 3.0% | 18 | 19 |

| AMS-I.E. | 11,504,715 | 6.3% | 651,188 | 0.8% | 10 | 37 |

| AMS-I.E. & AMS-II.G. | 0 | 0% | 0 | 0% | 0 | 1 |

| AMS-I.I. | 0 | 0% | 0 | 0% | 0 | 1 |

| AMS-I.K. | 0 | 0% | 0 | 0% | 0 | 1 |

| AMS-II.C. | 235,957 | 0.1% | 235,899 | 0.3% | 3 | 3 |

| AMS-II.C. & AMS-II.G. | 490,096 | 0.3% | 390,501 | 0.5% | 1 | 1 |

| AMS-II.G. | 39,537,619 | 21.8% | 14,855,629 | 17.1% | 308 | 441 |

| AMS-III.BG. | 97,331 | <0.1% | 1,505 | <0.1% | 1 | 1 |

| GS Cookstoves and Kitchen Regimes | 12,337,945 | 6.8% | 11,417,652 | 13.2% | 19 | 25 |

| GS Alternative Ignition | 199,262 | 0.1% | 197,825 | 0.2% | 13 | 13 |

| VMR0006 | 44,313,573 | 24.5% | 15,209,066 | 17.5% | 64 | 212 |

| VMR0006 & AMS-II.G. | 0 | 0% | 0 | 0% | 0 | 2 |

| VMR0006 & AMS-III.BG. | 3,444 | <0.1% | 0 | 0% | 1 | 1 |

| No Methodology Provided | 0 | 0% | 0 | 0% | 0 | 30 |

| Subtotal | 114,058,524 | 62.8% | 45,594,519 | 52.6% | 438 | 788 |

| Updated, New and Forthcoming Methodologies | ||||||

| GS Metered and Measured | 130,828 | 0.1% | 6,773 | <0.1% | 8 | 62 |

| GS Simplified Cookstoves | 4,460,027 | 2.5% | 2,418,156 | 2.8% | 244 | 337 |

| GS TPDDTEC | 61,109,665 | 34.3% | 38,764,809 | 44.6% | 186 | 424 |

| VM0050 | 240,406 | .1% | 29,485 | <0.1% | 2 | 9 |

| VM0050 & VMR006 | 332,296 | .2% | 2,690 | 0% | 2 | 2 |

| CLEAR | 0 | 0% | 0 | 0% | 0 | 0 |

| Subtotal | 66,273,222 | 37.1% | 41,203,913 | 47.4% | 442 | 834 |

| GRAND TOTAL | 180,331,746 | 86,798,432 | 880 | 1,6122 | ||

| Note: Some developers use more than one methodology as they are transferring from one registry to another, or so that they can implement more than one stove type. This is rare, impacting only 7 registered projects and 825,836 credits. Source: Barbara K Haya, Tyler Bernard, Aline Abayo, Xinyun Rong, Ivy S. So, Micah Elias. (2025). Voluntary Registry Offsets Database v2025-08, Berkeley Carbon Trading Project, University of California, Berkeley. Retrieved from: https://gspp.berkeley.edu/berkeley-carbon-trading-project/offsets-database. | ||||||

Appendix 3: RMI Risk Assessment

CMI reviewed resources from across the VCM and each credit type's sector to develop neutral, succinct risk profiles. We focused on the most crucial risks to quality, their drivers, how standards require projects to mitigate these risks, and how projects could mitigate these risks beyond the standard requirements. We mapped all of these factors to help stakeholders understand how to think about how to manage risk within a particular credit type.

We looked at both risk severity and prevalence, giving an average score for each based on all identified risks and their mitigation measures.

We define risk severity as the extent to which the identified risks threaten the integrity of the credit type. We reduce risk severity to match the effectiveness and feasibility of the current available and required mitigation measures in the literature. Our risk severity scoring options are as follows:

- High concern means the identified risks seriously impact project credibility. These risks either do not have mitigation measures, lack effective mitigation measures, or the mitigation measures are difficult to access or apply on the part of the project developer.

- Medium concern means the risks significantly impact project credibility, and mitigating the risks requires effort — or going above or beyond basic methodology or standard requirements — on the part of the project developer.

- Low concern means that the projects have some risk, but these risks are easily mitigated by the project, generally through methodology or standard requirements.

- Negligible concern means there is little or no risk to a given criterion, and mitigation is not necessary.

- Not enough information means there is no credible analysis or opinion in the literature on the relevant risks and mitigation measures that enable an informed decision.

We define risk prevalence as how likely it is that projects within the credit type encounter the risks we identified. To evaluate prevalence, we assessed the frequency with which credits would encounter each risk, regardless of whether the risk was mitigated. While the mitigation measures are incorporated in the severity score, mitigation feasibility or efficacy are not incorporated into the prevalence scope. Our risk prevalence scoring options are as follows:

- Very common means all or most credits in this type will encounter the risks identified (approximately 75% or more credits in the type).

- Common means many credits (approximately 30%–75% of credits in the type) will encounter the risks identified.

- Uncommon means fewer than half of all credits under the credit type will encounter the risks identified (approximately 10%–30% of credits in the type).

- Rare means none or almost none of the projects/credits in the credit type will encounter the risks identified (approximately 10% or less of credits in the type)

- Not enough information means there is no credible analysis or opinion in the literature on how often projects encounter these risks that enable us to make an informed decision.

Within each credit type, there may be multiple methodologies and activity types. We've generated risk profiles that provide the average risk severity and prevalence for the credit type broadly.

Example of Risk Scoring

Let's put this into perspective with an example: many nature-based credit types, like reforestation or grassland management credits, face challenges with non-permanence, meaning it can be hard to guarantee that carbon stays stored in trees or soil over time. Factors like wildfires, extreme weather, and pests are often outside the project developer's control, and because these risks are inherent to nature-based projects, a typical assessment might flag Permanence as "High Concern" and "Very Common."

Our analysis goes a level deeper, looking at how active methodologies and how project developers work to address that risk — for example, through buffer pool contributions required by registries, or additional tools like credit insurance and community-centered project design. If these mitigation measures are strong and widely adopted, we might downgrade risk severity to "Medium Concern," meaning the risk is still serious, but there are effective ways to manage it.

Appendix 4: Additional Resources on Cookstove Carbon Project Design and Quality

This analysis drew on guidance from across the VCM and the clean cooking sector. For more information on cookstove project best practices, risks, and accounting, see the following sources:

- BCTP: "A comprehensive quality assessment of cookstoves carbon credits"

- Berkeley Air Monitoring Group: Publication library

- CCA: Reports and Tools

- CCA: "The Principles for Responsible Carbon Finance in Clean Cooking"

- CCA: "Accelerating clean cooking as a nature-based climate solution"

- Modern Energy Cooking Services: "The Role of Voluntary Carbon Markets in Clean Cooking"

- MoFuSS Tool

Appendix 5: Data Sources

Our analysis relies heavily on the BCTP Voluntary Registry Offset Database, version August 2025. This explainer has made the following modifications to the data provided by BCTP for simplicity and clarity:

- Removed projects labeled as "Cookstoves" projects that use methodologies outside of the scope of this explainer:

- Removed one project (GS12102) with 0 credits earned, applying GS Methodology for Accreditation of Water Benefit Certificates as it was out of scope. This project does not earn carbon credits; rather, it earns water benefit certificates.

- Removed one project (GS10785) with 0 credits earned applying GS Methodology to Estimate and Verify Averted Mortality and Disability Adjusted Life Years (ADALYs) from Cleaner Household Air as it was out of scope. This project will not earn carbon credits but rather will earn credit for health outcomes (ADALYs).

- Searched project documentation for projects where methodology was labeled "Other," "Not Provided," or blank, and relabeled their methodology as either "Not Provided" (if no methodology could be found) or labeled with the appropriate methodology cited in project documents.

- Edited one project (VCS5173) with 0 credits earned, which was labeled as applying VM0006 Methodology for Carbon Accounting for Mosaic and Landscape-scale REDD Projects. After reviewing the registry entry, it was determined that the project was registered as using VMR0006. The project entry was edited accordingly and is now reflected in the data in this explainer.

- Projects were only factored into the analysis if their voluntary status was not listed as: "cancelled, inactive, registration and verification approval request denied, registration request denied, rejected by administrator, verification approval request denied, withdrawn, and blanks."

Acknowledgements

We are grateful to the Ripple Impact Fund, an advised fund of the Silicon Valley Communication Foundation, for their generous financial support for this project. We would like to also acknowledge the time, expertise, and input given by Elisa Derby of the Clean Cooking Alliance, April Allderdice and Sriskandh Subramanian of Micro Energy Credits, Ben Jeffreys of ATEC Global, as well as the Centigrade team, with special thanks to the input of Maddi Erdall. Additional acknowledgement to Brady Seals who was formerly with RMI, Annelise Gill-Wiehl of Columbia University, Rob Bailis of SEI, Michael Johnson of Berkeley Air Monitoring Group, and Donee Alexander and the team at Bridge Carbon for contributing their insights.